Pioneering as Castor Oil Manufacturer with World-Class Facilities

At Ambuja Solvex Pvt. Ltd., striving for utmost quality and perfection in producing castor oil products and castor oil derivatives is an ongoing and high-priority target. To achieve the following target we have established a top-notch infrastructure sprawling across a land area of 50,000 square yards and a built-up area of 20,000 square yards. Our well-equipped manufacturing unit is what distinguishes us from other castor oil companies. Moreover, we constantly strive for adapting to new technologies and improving every step of the manufacturing process.

Our Priorities in the

Constant Pursuit to Excellence

Research and Development

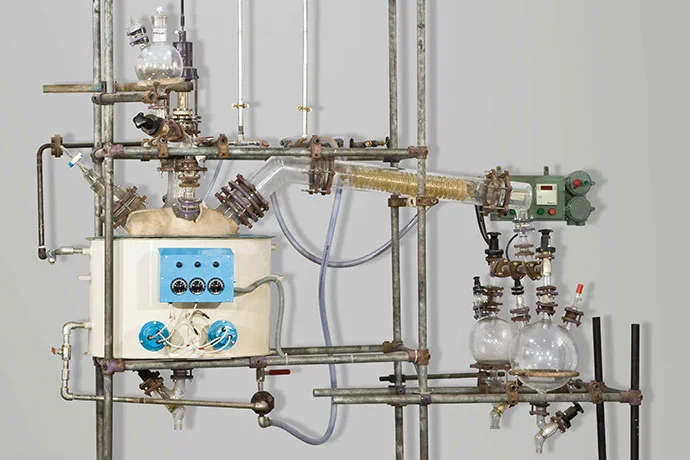

Recognizing the numerous castor oil applications and the importance industrial castor oil holds in the industry, ASPL has set up a state-of-art research and development center and a pilot plant. With an equipped analytical laboratory, we closely evaluate each and every product to supply the best quality to end-users.

Stability

As castor oil manufacturers we pay heed and ensure that the quality of products is maintained throughout their shelf life. Stability studies are conducted on our products as per International Toxicological standards.

Safety Assessment

Not only safety and quality, but we also provide accurate information about our industrial castor oil products. R & D is the foundation upon which our new product development strategy, process optimization, waste elimination, and cost reduction stand.

Housekeeping

Our dedicated FDA-registered facility follows rigorous procedures for cleanliness to maintain the quality & purity of the product. Final inspection and testing methods are followed to ensure conformity as per the protocols of international certifications.

Overview of

Our State-of-Art Infrastructure

Our dedicated FDA-registered facility follows rigorous procedures for cleanliness to maintain the quality & purity of the product. Final inspection and testing methods are followed to ensure conformity as per the protocols of international certifications.

Plant, Machinery & Infrastructure Details

| Title | Specifications |

|---|---|

| Land Area | 50,000 Square Yards |

| Built-up Area | 20,000 Square Yards |

| Total Reactor Capacity | 6 Cubic Meter |

| Size of Reactor | 0.5 KL to 1.5 KL |

| Types of Reactor | Stainless Steel – 316 |

| Reactor Pressure | Glass lined, Autoclave (S.S. – 316), Up to 15 Kg/cm2 |

| Mechanical Hydraulic Press | 2 Nos |

| Mechanical Screw Press | 2 Nos |

| Filters | Sparkler (S.S.- 316) |

| Reaction Temperature | Clarifier (P.P.), Centrifuge (S.S.- 316), 3°C to 280°C |

| Types of Reaction | Hydrogenation, Ethoxylation, Dehydration, Esterification, Distillation, Winterization, Neutralization, Bleaching |

|

In-house R&D center & Pilot Plant. In house container stuffing,palletisation and shrink. wrapping facilities. |

|

Plant, Machinery & Infrastructure Details

| Title | Specifications |

|---|---|

| Stainless Steel Autoclave | 5 liter (S.S.-316) |

| Stainless Steel Autoclave | 2 liter (S.S.-316) |

| Small Sparkler Filter | (S.S.-316) |

| Small Centrifuge | (S.S.-316) |

| Glass Assembly (100 Liter) | Reflux cum Dean & Stark facility |

| Glass Assembly (50 Liter) | Distillation facility |

Pilot Plant

| Title | Specifications |

|---|---|

| Boilers | Steam Boiler |

| Vacuum System | Hot Air Boiler (2,00,000 Kcal)s, Thermic Fluid Boiler (2,00,000 Kcal), Water Ring Vacuum Pump (5 & 10 HP) (S.S.) |

| Water Cooling Tower | 120 TR |

| Air Compressor | 5 HP with storage tank |

| State Electric Supply | 93 KW |

| In-house Power | 125 KW |

| Generator Supply | - |

Analytical Instrument

Spectrophotometer (UV-VIS), Polarimeter, Refractometer, Karl Fischer Moisture Apparatus, Lovibond Tintometer, Viscosity IS Cup, Soxhlet Apparatus, Titration Apparatus, Air Oven/Water Bath/Heating Mental, Thin layer chromatography, Melting point apparatus